So, here’s the deal with WoodCraft Furnishings. They make this super cool, high-end furniture, but they hit a major roadblock. Their main assembly line—the one that puts together all the fancy designs—started running really slow.

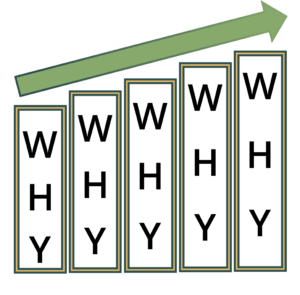

Orders were piling up, and customers were getting pretty frustrated. Instead of just buying new machines or blaming the workers, the bosses decided to use a strategy called the 5 Whys. It’s basically a way to keep asking “Why?” until you find the actual root of the problem.

Check out how they used it to fix their material shortage:

The 5 Whys In Action

1. Why are there so many delays on the assembly line?

The Answer: Because the workers are constantly stuck waiting for the materials they need, like specific wood pieces, screws, and glue.

2. Why aren’t the materials ready when the workers need them?

The Answer: Because the material bins are often empty, or the parts are buried under a bunch of other stuff in the warehouse.

3. Why are the material bins empty or disorganized?

The Answer: Because there isn’t a standard system to restock the bins before they actually run out. People just grab what they need until it’s all gone.

4. Why isn’t there a system for restocking materials?

The Answer: To be honest, the managers didn’t realize it was a problem. The assembly workers didn’t report it because they thought the warehouse team was already supposed to be tracking it.

5. Why was there such a big misunderstanding between teams? (The Root Cause!)

The Answer: There was no actual way for the assembly line and the warehouse team to talk to each other. They were basically working in total silence, so nobody knew when supplies were getting low.

The Fix: Better Communication

Once they realized the problem was just a lack of communication, the solution was actually pretty simple! They started a quick “stand-up” meeting every morning. Now, the assembly team tells the warehouse team exactly what materials they’ll need for the day.

They also set up a visual signal system (sometimes called Kanban). They put bright red markers in the material bins. When a worker reaches the red marker, it’s a signal to the warehouse that they need to bring more wood or glue right away – before the bin is totally empty.

The Happy Ending

After they started talking and using the visual signals, the delays totally vanished. The materials were always there right when the workers needed them. The factory started running like a dream, and everyone was way less stressed. It’s crazy how asking “Why?” five times can turn a huge mess into a smooth-running business!

Note: WoodCraft Furnishings is a fictional company I used to show how this works, but the “5 Whys” is a real strategy that subject matter experts use to solve big problems in the real world!